DeepWater Buoyancy Inc. is the world’s largest producer of subsea buoyancy products for the oceanographic community and has a vast product line of buoyancy solutions for offshore oil & gas, energy and technology companies.

This product portfolio has been built over the course of 35 years serving these industries. Though products are offered for shallow water applications, the company specializes in deepwater, providing solutions to depths of 6000 meters and beyond.

DeepWater Buoyancy’s headquarters and manufacturing operations are located in New England, the birthplace of syntactic foam.

At the heart of the DeepWater Buoyancy product line are the subsurface ADCP buoys. These buoys, originally developed for Teledyne RD Instruments’ ADCPs, are considered the gold standard within the industry. Consisting primarily of both spherical and elliptical buoys, the product line also includes the unique StableMoor® Mooring Buoys. DeepWater Buoyancy’s product line goes well beyond ADCP buoys. In the oceanographic market there are bottom mounts, instrument collars, and cable floats. For offshore oil & gas, there are installation blocks, modular buoys, deepwater marker floats and ROV buoyancy. In addition to DeepTec® syntactic foam products and custom-engineered components, there are also polyurethane and fabricated metal products for use subsea.

If a client can’t find their ideal solution in the product line, DeepWater Buoyancy will design and produce a custom product. The company’s design philosophy is, “A customer should have a product that meets the application, and not be forced to adjust their application to an off-the-shelf product.” Whether that is modifying an existing design or starting with a blank sheet of paper, the goal is to produce the finest, most cost-effective solution for any given application.

With a deep understanding of customers’ subsea operations, a long history of providing solutions to complex buoyancy applications, and a state of the art manufacturing facility, DeepWater Buoyancy is well-positioned to meet the challenges of this rapidly-evolving technology.

Product finder

Spherical ADCP Buoys

DeepWater Buoyancy understands the value of data recovery, as well as, ADCP technology, oceanographic operations and what it takes to supply products that ensure success.

Manufactured from high-performance DeepTec® syntactic foam, adjustable urethane and UHMW instrument clamps, and 316L stainless steel and titanium hardware, DeepWater Buoyancy’s ADCP Buoys are designed to outperform and outlast conventional mooring flotation.

Available with depth ratings to 6000 meters, they require minimal maintenance and are extremely durable under the most rigorous deepwater conditions.

Designed by an experienced engineering staff that fully understands the effects of mooring excursions on data quality, galvanic corrosion and biofouling, these buoys are performance-proven and have a long track record of successful deployment and recovery.

Elliptical ADCP Buoys

DeepWater Buoyancy understands the value of data recovery, as well as, ADCP technology, oceanographic operations and what it takes to supply products that ensure success.

Manufactured from high-performance DeepTec®syntactic foam, adjustable urethane and UHMW instrument clamps, and 316L stainless steel and titanium hardware, DeepWater Buoyancy’s ADCP Buoys are designed to outperform and outlast conventional mooring flotation.

Available with depth ratings to 6000 meters, they require minimal maintenance and are extremely durable under the most rigorous deepwater conditions.

Designed by an experienced engineering staff that fully understands the effects of mooring excursions on data quality, galvanic corrosion and biofouling, these buoys are performance-proven and have a long track record of successful deployment and recovery.

Elliptical ADCP buoys have lower drag for a given buoyancy than spherical buoy and significantly lower drag than glass or plastic spheres.

Stablemoor Mooring Buoys

Specifically engineered for high current applications, the StableMoor® is designed to reduce drag and increase mooring stability in extreme flow regimes. By decreasing frontal area (compared to our standard spherical buoys) and increasing dynamic stability in high current areas, the StableMoor® minimizes mooring inclination and excursions.

The StableMoor® is cast from a buoyant core of solid DeepTec® syntactic foam and wrapped in a protective layer of GRP that provides a smooth and durable exterior. The high-strength GRP tail and 316L stainless steel mooring swivel allow for smooth transitions from changes in current direction and provide increased directional stability. Best of all, instruments can be installed and removed in minutes without the need to disassemble the unit.

This versatile instrument platform can be provided with single or multiple instrument wells to support upward, downward, or upward and downward looking configurations.

Models with two instrument wells can be fitted with a single ADCP cable to an external battery case or with other instrumentation. Instrument wells can be covered by an LDPE acoustically transparent window, further reducing drag without compromising instrument performance. Like other DeepWater Buoyancy mooring products, the StableMoor® can be customized for acoustic modems and supplied with pockets for mooring location devices, CTDs, and other remote sensing equipment.

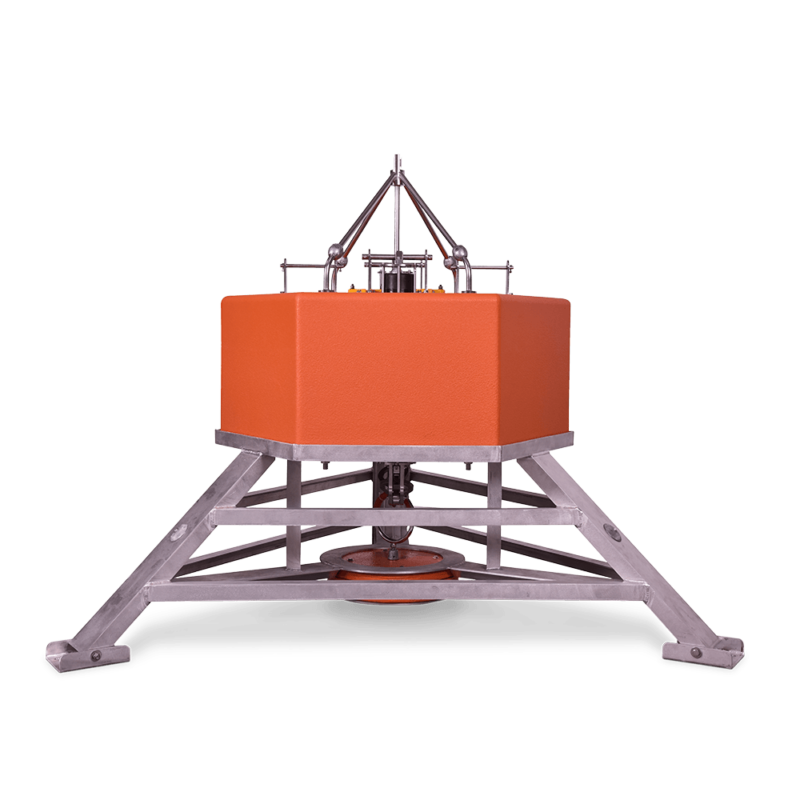

ADCP Inline Mooring Frames

ADCP Inline Mooring Frames are designed to allow ADCPs to be mounted in a mooring string, passing the mooring loads around the instrument. Standard designs accommodate a single high-frequency ADCP, a high-frequency ADCP with an external battery pack or two high-frequency ADCPs in an upward and downward-looking configuration. The largest versions support a single mid-frequency device.

Frames are manufactured with 316L stainless steel. The frames are then electropolished and fitted with replaceable zinc anodes for superior corrosion resistance. Upper and lower bails are fitted with isolation bushings and allow connection to the mooring line with standard shackles. The clamps are adjustable for ease of use with varying instruments and are lined with an elastomeric sheet to secure the instruments from damage, while isolating them from the frame.

Our extensive in-house design, machining, metalworking, and welding capabilities allow us to make an endless variety of these frames to support and protect not only ADCPs, but also a wide range of other instrumentation. DeepWater Buoyancy’s engineering staff will work with you to design the exact frame that best meets the needs of your equipment, pass through loads, and time at depth.

Instrument Bottom Mounts

DeepWater Buoyancy’s BTM-AL50 bottom mounts are designed for ADCP deployment in shallow ocean waters, rivers, coastal areas, and anywhere else where the size and remote recoverability of the AL-200 and AL-500 TRBM are not required.

These rugged diver-serviceable tripods come ready to accept your ADCP and battery canister, and can be modified to fit CTD, wave / tide gauge, velocimeter or other instrumentation.

BTM-AL50’s are manufactured using 5000 series aluminum, galvanically-isolated fasteners, and are fitted with zinc anodes for superior corrosion resistance. The double axis gimbal keeps your ADCP oriented to vertical after deployment and is manufactured using ultra-high molecular weight polyethylene to deter marine growth.

The units' three foot pads are supplied with through holes for ballast or for spiking, depending on your application. Standard (10lb/4.5kg) urethane-coated ballasts are provided for each of the three legs. Additional ballast is available upon request.

Trawl-Resistant Bottom Mounts

These rugged deployment products are designed to protect instrumentation in areas where trawling is a concern. The AL-200 and AL-500 Trawl-Resistant Bottom Mounts (TRBMs) consist of a buoyant recovery pod designed to permit retrieval of all mounted instruments. The recovery pod is ejected from the base by a user-supplied acoustic release and trails a Spectra recovery line that is attached to the base. The aluminum base can then be winched aboard. Disposable concrete bases can also be provided depending on bottom conditions.

Conditional upon the specific requirements, acoustic recoverable systems are offered for deployment depths of up to 1000 meters. All models feature a special grade of high impact DeepTec® syntactic foam and 5000 series aluminum construction. Adjustable amounts of lead ballast in the base allow the in-water weight of the TRBM to be tailored to specific bottom conditions.

Pop-Up Buoy Recovery System

DeepWater Buoyancy’s Pop-Up Buoy Recovery System (PUB) allows for direct retrieval of seabed packages, such as anchors, anchor lines, and bottom-mounted frames with instruments. Once the acoustic release is activated and completes its disconnection, the buoy lifts free from the canister and rises to the surface. A synthetic line connects the buoy directly to the framework of the seabed item and allows for retrieval.

The standard PVC canister holds 75 meters of 1/4″ synthetic line. (Other line lengths are available upon request.) The recovery buoy is made from high-strength DeepTec® solid syntactic foam which is finished with an abrasion-resistant, polyurethane elastomer coating.

The canister subassembly has attachment features to permit various mounting configurations, including easy mounting to our BTM-AL50 tripod bottom mounts.

Our standard recovery systems are shown below. We also offer custom recovery systems.

Hydro-float Mooring Buoys

DeepWater Buoyancy’s spherical subsurface mooring buoys provide exceptionally reliable buoyancy for a variety of oceanographic, commercial, military and offshore applications. Made from DeepTec® syntactic foam, Hydro-float® Mooring Buoys (HMBs) offer a low-maintenance and cost-effective solution for subsurface moorings and other offshore applications.

Because of their solid construction, these buoys may be cast with through holes and instrumentation pockets on any axis without compromising reliability. Clamps and mounting hardware can be added for any user-supplied instrumentation. HMBs come in many standard sizes and can be customized to meet specific needs. While spheres are used in a wide range of flow regimes, elliptical buoys or streamlined designs, like our StableMoor®, are also offered, further reducing drag on moorings in high current areas. HMB’s can be fitted with integral tail fins providing additional stability while minimizing stress on rigging.

Subsea Cable Floats

DeepWater Buoyancy’s line of Subsea Cable Floats provide low-drag distributed buoyancy for a variety of offshore, commercial, military and oceanographic applications. Available in a wide range of sizes, three different attachment styles, and with internal diameters sized to fit a wide array of cables, these floats are some of the most versatile buoyancy products available. All cable float offerings are available in depth ratings from 750 meters to 6000 meters.

Quick-Loc® cable floats feature a hinge and latch system for frequent deployment and recovery during ROV operations. Bolt-on style floats are designed for longer term deployments such as deep water moorings. A band clamp style of attachment is reserved for our smaller cable float offerings in order to maximize the buoyant force provided by each unit.

As standard, cable floats are offered with type 316 stainless steel hardware. Titanium or composite hardware may be specified, based on an application’s requirements.

HD series cable floats are ideal for large diameter armored cables and control umbilicals. Designed to handle the stresses caused by cable bending, HD style cable floats are designed with internal polyurethane elastomer inserts. These polyurethane elastomer inserts provide maximum grip and allow the cable to flex to its minimum bend radius without damaging the cable or flotation.

Marker Floats

Rugged and highly visible, our marker floats are used in ROV and Survey operations around the world. Due to their unique acoustic signature and high visibility coloration they are a popular choice for marking bottom location to facilitate ROV maneuvering.

Whether in the traditional “football” shape or in the newer stackable, “square” form, these units are extremely reliable. They can’t leak or implode. Constructed with a tough, rotationally-molded exterior shell and a solid DeepTec® syntactic foam core, these products endure even the roughest handling on deck.

Instrument Collars

Designed for long term submergence, our instrument collars provide years of reliable service and stand up to rough handling during operations. Each collar yields the buoyant force needed for a rapid ascent and positive recovery without impairing the performance of the instrument. From shallow water surveys to ultra-deepwater positioning, you can count on these collars to help ensure overall success in the field.

These products are manufactured from a buoyant core of DeepTec® solid syntactic foam and are depth rated to 1000, 3000 or 6000 meters. A tough, rotationally-molded exterior shell provides superior impact and abrasion resistance. Polyurethane elastomer inserts are designed to put a soft, sure hold on the instrument housing. Fasteners can be provided in stainless steel, super duplex or titanium.

Standard designs and custom solutions are available. Standard collars are currently available to fit most instrumentation from the following manufacturers: Sonardyne, Nautronix, Applied Acoustics, ASL Environmental Sciences and Kongsberg Maritime.

HardBall® Floats

HardBall® Floats from DeepWater Buoyancy provide distributed buoyancy for cable laying, offshore, and oceanographic applications. They are available in a wide range of sizes and depth ratings, and only the highest strength, epoxy-based DeepTec® syntactic foams are used to form the core — no macrospheres or other high risk materials. For maximum durability, a thick-walled polyethylene exterior shell provides superior resistance to impact and biofouling.

A great alternative to glass spheres on deepwater moorings, HardBall® Floats offer in-line or back up buoyancy that doesn’t require maintenance and cannot implode at depth.

HardBall® Floats can also be rigged to pass across an overboarding sheave during deployment and recovery. This feature makes them ideal for use on the tethers and umbilicals of sea plows and other trenching vehicles. A unique attachment kit is available that allows each float to be quickly and securely clipped and unclipped from the cable. Unlike glass spheres or hollow steel and plastic floats, HardBall® Floats cannot leak or implode.

Modular Buoy System

Modular buoys are the most versatile approach for offshore applications. They are offered in a variety of standard sizes with buoyancy as great as 2 metric tons and depth ratings to 3000 meters and beyond. For installation of pipeline sleds, jumpers, or suspended moorings, this multi-purpose product offers a straightforward way to meet buoyancy requirements.

Our modular buoys are made from high-strength DeepTec® solid syntactic foam that is cast into extremely durable, rotationally-molded polyethylene shells or finished with FRP. Only the highest strength, epoxy-based materials are used to form the buoyant core. Modules interlock for added strength and can easily be repaired or replaced.

The modular hardware design consists of an adjustable central strength member that accommodates the addition or subtraction of buoyancy modules. Most commonly supplied with a pad eye configuration, we offer a wide range of custom end fittings. To protect against corrosion during long-term deployments, all steelwork can be epoxy coated or hot dipped galvanized. All hardware can also be supplied in stainless steel or titanium. End fittings can also be specified “ROV compatible”.

With rugged construction and the use of the world’s most reliable, field-proven, syntactic foams, these truly modular buoys provide offshore users with years of trouble-free service

MiniMod™ Small Modular Buoy

Our modular buoys are the most versatile approach for offshore applications. They are offered in a variety of standard sizes with buoyancy as great as 2 metric tons and depth ratings to 6000 meters. For installation of pipeline sleds, jumpers, or suspended moorings, this multi-purpose product offers a straightforward way to meet buoyancy requirements.

Our MiniMod™ small modular buoys are designed for lighter applications. Still rated to depths as great as 6000 meters, the standard 7-module buoy can provide up to 325 kg of buoyancy. Made from high-strength DeepTec® solid syntactic foam that is finished with an abrasion-resistant, polyurethane elastomer coating, these buoys can stand up to rough handling on-deck and in the water.

The syntactic foam modules are held together and handled by use of synthetic straps, as opposed to metal hardware. These straps have numerous benefits including corrosion resistance, ease of handling, and no loss of buoyancy. Modules interlock for added strength and can easily be added or removed for your application.

With rugged construction and the world’s most reliable, field-proven syntactic foams, these truly modular buoys provide offshore users with years of trouble-free service.

Mooring Line Cable Fairing

Under certain flow conditions, taut mooring lines can vibrate or “strum”. The strumming is caused by vortices that result from the water passing over the line diameter. Strumming not only creates cable fatigue, it can have a detrimental effect on instruments in the mooring string.

Our mooring line fairings reduce strumming by eliminating this vortex action. Additionally, they reduce drag on the mooring line resulting in less mooring layover and less fatigue on the line. The drag coefficient for a 3/8” jacketed wire cable is 1.20, whereas the mooring line fairing is 0.17. This is an improvement of over 85%.

Fairings are made of durable ABS plastic. They are easily loaded onto a taut mooring line during deployment simply by separating the ends of the fins and installing over the line.

Unlike other solutions, our product can be installed over select portions of the line, requires no maintenance, does not suffer from tangling problems, and resists biofouling.

The standard units are designed for 1/4″ and 3/8″ jacketed wire rope and are 12” in length. Other diameters and lengths can be produced upon request. End clamps are also available to limit the vertical movement of the fairing on the line.

ROV Buoyancy

We provide the highest quality flotation for offshore, research, commercial and military vehicles. Made with DeepTec® syntactic foam, these floats are the most reliable and cost-effective choice for ROV, AUV and tow body flotation. Whether you are outfitting a new vehicle or tooling package, or require customized add-on buoyancy, you will get a superior product and quick turnaround.

ROVits

Designed similarly to “tether balls”, the ROVit® is DeepWater Buoyancy’s answer to the request for multi-purpose, small floats. ROVits® provide buoyancy to make manipulator and ROV tasks easier—especially where lift eyes, pins, and handles are involved.

Each ROVit® is produced from DeepTec® solid syntactic foam and provides approximately 0.03 kg of uplift. Fifteen ROVits® equal approximately 0.45 kg of buoyancy.

The ROVit® is available for 3000 or 4000 meter operating depth. Their rugged design and deep rating make them the most versatile tools in your support van.

Prefer a different shape, size or depth rating for your buoyancy needs?

Please ask. We are a full-service design and manufacturing operation. We are glad to work with you on custom applications, including ROV blocks, skid buoyancy and buoyancy for ROV tools.

Polyurethane Elastomer Products

To complement our line of DeepTec® syntactic foams, we also produce a wide range of polyurethane products for deep submergence. Custom clamping solutions, protective coatings and flexible cable products can be cast in any size or durometer.

ADCP Buoy Frames

In the early days of acoustic doppler current profilers (ADCPs) most units on the market were designed with four transducer beams. To most effectively accommodate these four-beam ADCPs, buoys were produced with four tie-rods that pass through the buoy and end frames with four legs that attach to the tie-rods. This design allowed for the beams of the ADCP to pass between the frame legs, unobscured.

Advances in ADCP technology have since led to ADCPs with as few as three beams and as many as nine transducer beams. In some cases, a center (vertical) beam is included in the configuration. These technological advances in ADCP design have led to changes in the design of the framework for ADCP buoys.

In the case of a three-beam ADCP, buoys are now offered with three tie-rods and end frames with three legs that pass between the beams. For customers who have previously purchased a buoy outfitted for a four-beam ADCP, but now look to use a three-beam ADCP, a frame is available that mounts on the four tie-rods and transitions to three legs to pass between the beams. Additionally, a buoy can be outfitted with a four-beam frame on one end and a three-beam frame on the other for compatibility with both systems.

When a buoy is at the top of a mooring and a vertical beam is used, or when an ADCP with several beams is used, typical frames would block the beam or beams. And since the buoy is at the top of the mooring string, the need for a top arbor is eliminated. In this case a ring frame is used. This frame serves to protect the ADCP head during deployment, recovery, and handling on the deck of a vessel, but will not obstruct the beam pattern.

All frames are manufactured with 316L stainless steel. The frames are then electropolished and fitted with replaceable zinc anodes for superior corrosion resistance. Frames with arbors on them are fitted with isolation bushings and allow connection to the mooring line with standard shackles.

Our extensive in-house design, machining, metalworking, and welding capabilities allow us to make an endless variety of these frames to support and protect not only ADCPs, but also a wide range of other instrumentation. DeepWater Buoyancy’s engineering staff will work with you to design the

exact frame that best meets the needs of your equipment, pass through loads, and time at depth.

Benthic Lander

DeepWater Buoyancy’s Benthic Lander allows for deployment of instruments to the seafloor to depths as great as 6000 meters. The design provides for a dual acoustic release system for release redundancy. It is highly-customizable and can accommodate a variety of instruments. The unit is designed to remain on the seafloor until the acoustic releases are activated.

Release activation causes the ballast pack to be dropped. The loss of weight from the dropping of the ballast leaves the unit positively buoyant and it ascends to the surface. The base frame is manufactured with 5000 series marine aluminum. The recovery buoy is made from high-strength DeepTec® solid syntactic foam that is rated to the application’s deployment depth and, unlike hollow glass balls, carries no risk of implosion.

The foam is finished with an abrasion-resistant, polyurethane elastomer coating. Additional framework is fabricated from 316 stainless steel and are electropolished for superior corrosion resistance. The unit is suited for both shallow and deep water applications but is not designed for trawl resistance. For applications in trawling areas, please see our Trawl-Resistant Bottom Mount.

Jumper Buoyancy

Jumpers and Tie-in Spools are sections of pipe that connect subsea oilfield equipment. Buoyancy is often added to these structures to decrease the load on the terminations. DeepWater Buoyancy produces Jumper Buoyancy in both a standard cylindrical form, as well as with integrally-molded helical strakes.

The standard Jumper Buoyancy modules are fabricated with either a rotationally-molded polyethylene shell or with a GRP skin. In all cases, high-performance DeepTec® syntactic foam provides the buoyancy. An integral elastomeric clamp acts as the interface to the pipe and resists axial and torsional loads.

Straked modules are provided to decrease vortex-induced vibration (VIV). These designs have integral helical strakes and keying features to ensure alignment of the helix from module to module.

Compression of the clamp is maintained by either standard hardware or by strapping systems. In either case, installation tools are provided to create the required compression for elastomeric components.

Umbilical Buoyancy

Umbilical Buoyancy from DeepWater Buoyancy provides distributed buoyancy for platform-to-seafloor umbilical applications. Available with either an integral or secondary clamp, these modules can be custom to fit any umbilical of any size or configuration. Umbilical Ballast modules are also available to assist in the creation of the proper umbilical arrangement.

All modules are custom-designed to each application by taking into consideration the designed uplift, umbilical specifications, and deployment strategy. Modules have a buoyant core of high-performance DeepTec® syntactic foam within a rotationally-molded polyethylene shell.

The standard design has an integral elastomeric clamp designed to secure the modules against axial and torsional loads. Compression of the clamp is maintained by either standard hardware or by strapping systems.

Optionally, a separate inner clamp can be provided consisting of syntactic foam sections with a composite strap assembly. In this case, the buoyancy module is installed around the inner clamp and is free to rotate about the inner clamp. In either case, installation tools are provided to create the required compression for the elastomeric component.

Pipeline Buckle Mitigation Buoyancy

Under certain conditions, subsea pipelines can experience lateral movement known as “buckling”. Lateral buckling causes the pipeline to be dragged across the seafloor, which can jeopardize the pipeline’s integrity. In response to this, Pipeline Buckle Mitigation Buoyancy modules are clamped onto the pipeline to control the formation of the lateral buckles and to alleviate stress. These modules decrease the lateral friction from the buckle by both reducing weight of the buckling sections and by providing a protective shell.

All modules are custom-designed to fit each application taking into consideration the designed uplift, pipeline specifications, and deployment strategy. The standard design has an integral elastomeric clamp designed to secure the modules against axial and torsional loads. All units are made using high-performance DeepTec® syntactic foam inside a thick-walled polyethylene exterior shell that provides superior resistance to impact, wear and biofouling.

Compression of the clamp is maintained by either standard hardware or by strapping systems. In either case, installation tools are provided to create the required compression for the elastomeric component.

Acoustic Release Buoyancy

DeepWater Buoyancy’s Acoustic Release Buoyancy Collars allow for long term deployment of acoustic release instruments to depths as great as 6000 meters. Designs provide for single acoustic release systems or, for redundancy, dual/tandem release systems. Acoustic Release Buoyancy Collars are highly customizable and can accommodate a variety of releases from numerous manufacturers.

These units can be configured for shallow or deep water applications and are critical as a fail-safe recovery system for your acoustic releases in case of damage to the mooring above.

These collars are made from high-strength DeepTec® solid syntactic foam. Unlike hollow glass spheres, these solid foam floats carry no risk of implosion. The foam is finished with an abrasion-resistant, polyurethane elastomer coating. All hardware is fabricated from either 316 stainless steel or titanium, depending on the application.

All Acoustic Release Buoyancy Collars are custom designed and manufactured to fit particular specifications to ensure instrument recovery.

Floating Offshore Wind Cable Buoyancy

DeepWater Buoyancy’s Floating Offshore Wind Cable Buoyancy provides distributed buoyancy for cables used in floating wind applications. This buoyancy can reduce top tension loads, as well as support compliance in the cable during movement of the floating platform.

Modules are custom-designed for each application, taking into consideration the required uplift, cable specifications, and deployment strategy. Designs are verified through finite element analysis and validated with in-house testing.

Modules have a buoyant core of high-performance DeepTec® syntactic foam within either a rotationally-molded polyethylene, polyurethane or fiberglass shell. These modules are designed with an integral elastomeric clamping system that allows the modules to remain securely in place, resisting both axial and torsional loads. Compression of the clamp is maintained by either standard hardware or by strapping systems.

In addition to Buoyancy Modules for the cables, DeepWater Buoyancy also provides Ballast Modules for the cables and Mooring Line Buoyancy.

Contact us

Saderet Limited

Unit C1

Eden Business Park

Cooil Road

Braddan

Isle of Man

IM4 2AY

Tel.: +44 (0)1624 880366

Email: [email protected]

Registered in the Isle of Man 120826C

VAT Reg. No. 003 1066 44